How Long Should Water Softener Resin Last?

Water softener resin is a critical component in commercial water filtration systems and industrial water softeners, responsible for removing hardness ions like calcium and magnesium from water. This process helps businesses maintain efficient operations, protect equipment, and meet quality standards.

For industries such as manufacturing, food and beverage, and healthcare, maintaining water quality is essential to ensure smooth operations and compliance with strict regulatory standards. Factors such as water quality, resin maintenance, and system usage play a significant role in determining how long water softener resin remains effective. Proactively maintaining systems and recognising signs of wear can help businesses optimise efficiency, reduce costs, and avoid downtime.

What is Water Softener Resin?

Water softener resin is an essential element in industrial water filtration systems and commercial water softeners, designed to remove hardness ions like calcium and magnesium from water. These ions, when left untreated, can lead to scale buildup in pipes, boilers, and other critical equipment, reducing efficiency and increasing maintenance costs.

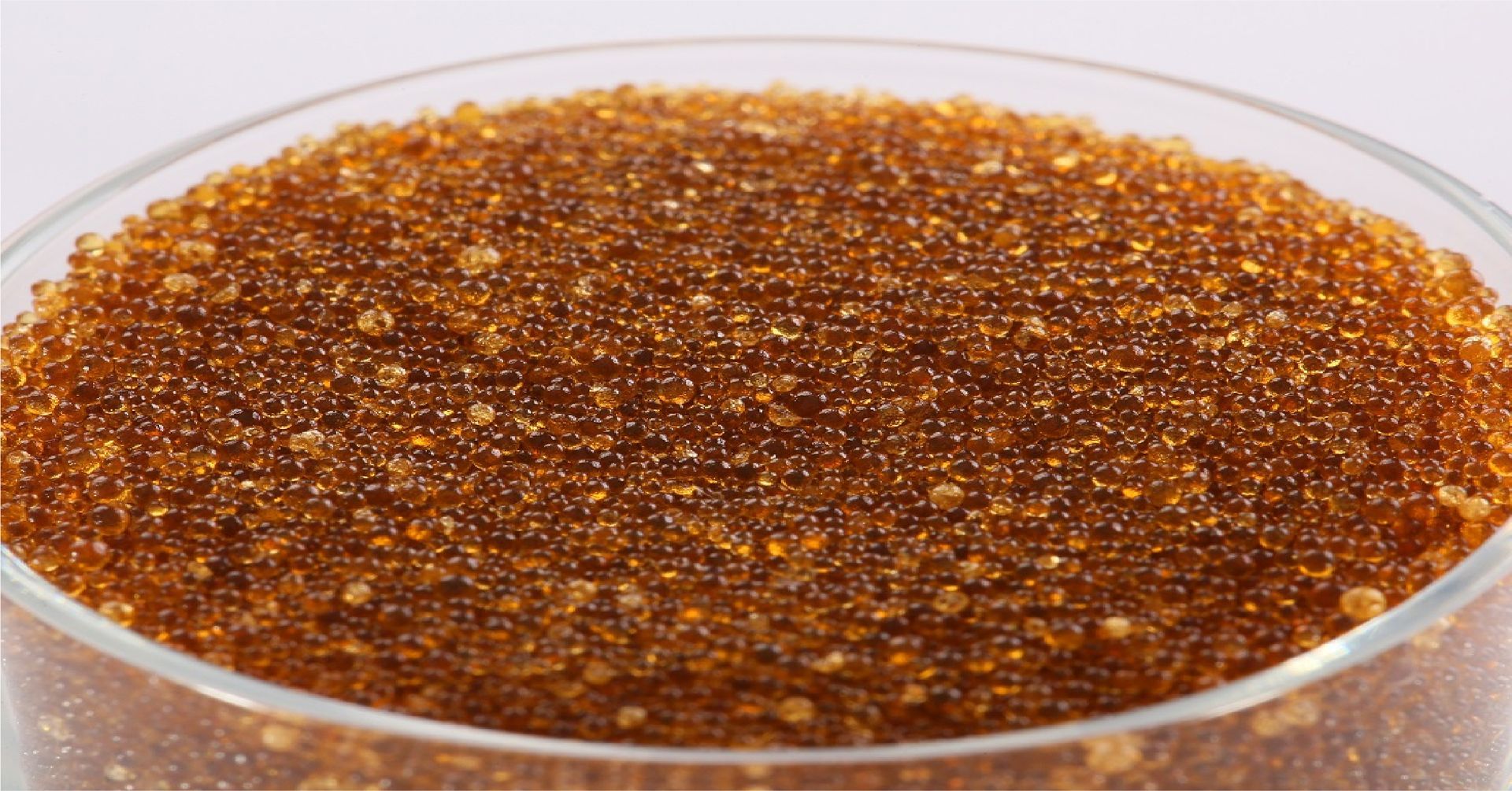

At its core, water softener resin consists of tiny, bead-like structures made of durable polymer materials. These beads are coated with functional groups that attract and exchange hardness ions with harmless sodium or potassium ions as water flows through the system. This process, known as ion exchange, ensures that the water exiting the system is softened and free of damaging minerals.

In industrial settings, where large-scale water usage is common, maintaining the efficiency of a water softener is crucial for uninterrupted operations. High-quality resin not only improves water quality but also enhances the performance and longevity of expensive machinery and infrastructure. Properly functioning resin ensures that water meets the specific requirements of industries such as manufacturing, healthcare, and food production, where precision and reliability are paramount.

How Long Does Water Softener Resin Typically Last?

The lifespan of water softener resin can vary depending on several factors, but under optimal conditions, high-quality resin has the potential to last between 10 to 15 years. However, the actual lifespan often depends on the quality of the water being treated, the frequency of system usage, and the overall maintenance practices in place.That said, industrial and commercial use often results in shorter lifespans (between 3–5 years).

The Impact of Water Quality

Water quality is one of the most significant factors affecting resin lifespan. Hard or contaminated water containing high levels of iron, chlorine, or organic compounds can degrade resin more quickly. For industries relying on commercial water filtration systems, untreated water may introduce contaminants that poison the resin and reduce its effectiveness.

The Role of Resin Quality

The quality of the resin itself also plays a crucial role. Premium-grade resin tends to last longer and maintain better performance over time. Lower-grade options may require more frequent replacements, especially in demanding industrial water softener maintenance settings.

System Usage in Industrial and Commercial Environments

Industrial systems with high water throughput often subject resin to more frequent regeneration cycles. Over time, this repeated process causes wear and tear on the resin beads, reducing their mechanical strength and efficiency. This is especially true for industries with continuous water demands, such as manufacturing or food production.

Comparing Residential and Industrial Usage

While residential water softeners generally see less wear and can use resin for over a decade with minimal maintenance, industrial water softeners often operate under more challenging conditions. In these environments, resin may need replacement every 3 to 5 years due to higher water volumes, greater exposure to contaminants, and the physical strain of repeated regeneration cycles.

Signs It’s Time to Replace Resin

Water softener resin plays a vital role in ensuring the efficiency of commercial water filtration systems and industrial water softeners. However, like all consumable components, resin will eventually degrade over time. Recognising the early signs of wear or failure can help businesses avoid costly downtime and maintain operational efficiency.

Reduced Water Quality

One of the most obvious signs that resin needs replacement is a noticeable decline in water quality. If hardness ions like calcium and magnesium are no longer being effectively removed, you may experience issues such as scale buildup in pipes and machinery or inconsistent water softening results.

Frequent Regeneration Cycles

When the resin loses its capacity to hold and exchange ions efficiently, the system will require more frequent regeneration cycles. This not only increases operational costs but also reduces the overall efficiency of the water softener, impacting productivity in industrial water softener maintenance settings.

Discoloured or Yellowed Water

Resin degradation can lead to water becoming discoloured, often with a yellowish tint. This can indicate that the resin beads are breaking down and releasing particles into the water supply, compromising the system’s performance and potentially contaminating equipment or processes.

Resin Beads in the System

Visible resin beads in the water supply or within the system’s components are a clear sign that the resin bed has deteriorated. This can result from mechanical wear, structural failure of the resin beads, or improper maintenance.

How Failing Resin Affects Operations

Failing resin can lead to increased maintenance needs, reduced equipment lifespan, and higher energy costs. For businesses relying on water filtration for businesses, these issues can disrupt operations, increase costs, and even compromise regulatory compliance.

How to Extend the Lifespan of Water Softener Resin

Maximising the lifespan of water softener resin is essential for maintaining the efficiency of commercial water filtration systems and industrial water softeners. Proper care and proactive maintenance can significantly reduce replacement frequency, saving time and operational costs.

Regular Maintenance and Inspections

Routine maintenance is crucial for preventing resin degradation. Scheduling periodic inspections ensures that the system operates efficiently, identifies potential issues early, and allows for timely adjustments or repairs. AP Water’s industrial water softener maintenance services can help businesses stay on top of their system needs.

Pre-Treatment of Water

Installing pre-treatment systems such as activated carbon filters can remove harmful contaminants like chlorine and chloramines, which can degrade resin over time. These filters are particularly effective at protecting resin from chemical damage, extending its performance and durability.

Pressure Regulation

High incoming water pressure can cause hydraulic shock, leading to mechanical wear and damage to resin beads. Installing a pressure regulator helps maintain stable water flow, minimising unnecessary strain on the system and resin.

Use of Resin Bed Cleaner

Adding a specialised resin bed cleaner to the brine tank during each salt refill can mitigate fouling caused by iron and manganese. This simple step can prevent common issues like clogging and inefficiency, maintaining the resin’s ion exchange capacity.

Quality Salt and Resin Choices

Using high-purity salt for regeneration and opting for premium-grade resin ensures better performance and a longer lifespan. Inferior materials may introduce impurities or fail to perform under demanding conditions, increasing maintenance needs.

Water Quality Monitoring

Regularly testing water quality helps identify changes in contaminant levels that could impact resin performance. Adjusting system settings or introducing additional filtration solutions based on test results ensures consistent water softening results.

Partner with AP Water for Reliable Water Softening Solutions

Maintaining the performance and longevity of your industrial water softener or commercial water filtration system requires expert care and tailored solutions. AP Water’s team of professionals is here to provide the guidance and support you need to optimise your water systems, enhance operational efficiency, and reduce costs.

Whether you’re dealing with resin replacement, system maintenance, or upgrading your filtration solutions, AP Water offers customised expertise to keep your business running smoothly.

Reach out to AP Water today for a consultation and let our experts tailor the perfect solution for your business. Call us at +61 3 9534 3674 or email us at admin@apwater.com.au to find out how we can support your water filtration needs with tailored solutions for your industry.